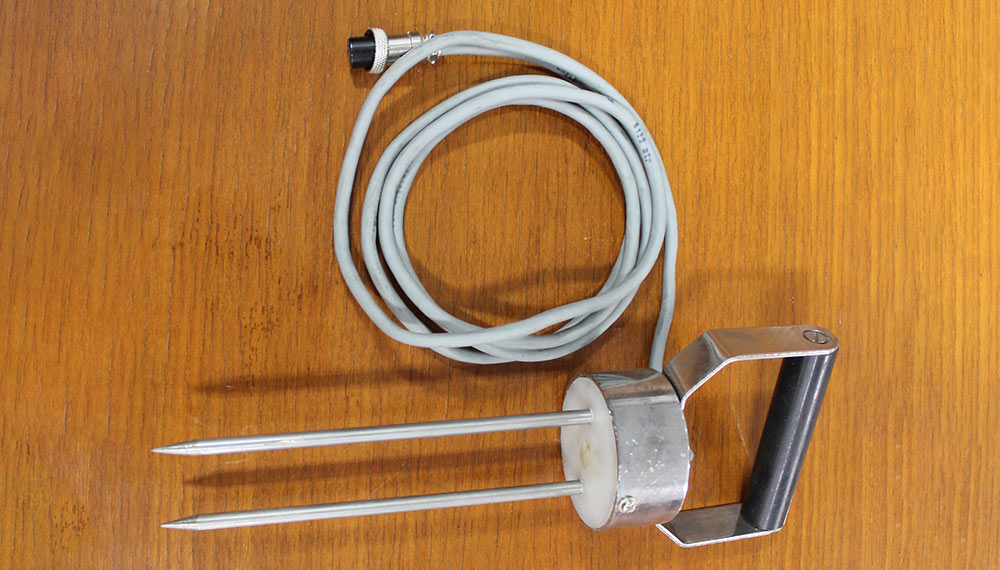

Digital Jute Moisture Meter

Digital Jute Moisture Meter

IJIRA is popularizing a novel digitalized solution to the problem of jute fiber and jute products Moisture Regain percentage value estimation. This approach is based on application of current knowledge in the field of instrumentation and automation to move forward towards digitalization of jute trade and production, in order to provide a non controversial analysis in turns of cost accuracy and consistency of result.

The newly developed IJIRAs moisture meter neither requires extensive training nor makes use of heavy, non removable specialized hardware or tools that either difficult to operate or makes movement uneasy and uncomfortable.

The first model of IJIRA moisture meter came way back in 1957. And there after improved versions of IJIRA moisture meter came in the market on regular interval. Finally IJIRA entered into digital world and brought digital version of the moisture meter in the market somewhere in 2016. The adaptation of this version took sometime but slowly most of the stake holders started accepting it. IJIRA even then was not satisfied with this version and through exhaustive market survey and experiences of the customers using this moisture meter IJIRA came to know its limitations, with respect to authenticity of the output shown by someone. In order to overcome any chances of ambiguity IJIRA felt that it is important not only to have moisture data on screen but also available through an android app. IJIRA then started developing android application for capturing Moisture Regain percentage data from moisture meter and input information from user, in order to provide an extensive report which could be stored for later use or can be sent any where trough internet. Accumulation of large amount of such data can also through light on Moisture Regain percentage variation from place to place as well as from season to season. This will be perhaps first attempt in the history of jute trade that such type of knowledge will be collected for transparency in the jute trade.

References

Aleksandra Ivanovska, Jelena Lađarević, LeposavaPavun, Biljana Dojčinović, Ilija Cvijetić, DušanMijin, Mirjana Kostić, “Obtaining jute fabrics with enhanced sorption properties and “closing the loop” of their lifecycle, Industrial Crops and Products, Volume 171, 2021, 113913, ISSN 0926-6690, https://doi.org/10.1016/j.indcrop.2021.113913. (https://www.sciencedirect.com/science/article/pii/S0926669021006774)

Jute and circular economy

Jute is increasingly becoming a part of circular economy. This means that every part of the plant to the fiber as well as waste materials have utility and economic use. As a biodegradable fiber, jute and jute waste, turned into products, can effectively return to the soil when the utility of the product has run its life cycle. Jute creates a sustainable future and economy to mitigate the impact of climate change. Jute is supportive of communities that grow, produce, process, and consume it.

Abstract: The objective of this investigation was to obtain jute fabrics with enhanced sorption properties (by using simple and cost-effective alkali and oxidative modifications) and a long life cycle. The applied alkali modifications lead to hemicellulose removal and decreased the fibers’ crystallinity, both contributing to enhanced fibers’ sorption properties, i.e., water retention power and degree of fibers’ swelling up to 49 % and 70 %, respectively. A connection between cellulose polymorphs’ (cellulose I and cellulose II) contents (determined by XRD), fibers’ surface morphology (verified by FESEM), fabrics’ crimp, and capillarity of jute fabrics modified with 17.5 % NaOH was established. During the oxidative modifications, significant changes in jute fibers’ chemical composition and structure (i.e., lignin removal and more homogeneous middle lamellae) occurred which further resulted in enhanced jute fabrics’ water retention power and capillarity as well as fibers’ swelling up to 80 %, 75 %, and 54 %, compared to the raw jute, respectively. In order to move towards a circular economy and to ensure the recycling and re-use of recycled fabrics, the jute fabrics with enhanced sorption properties were evaluated as biosorbents for anthraquinone dye C. I. Acid Blue 111. The obtained results revealed that the jute fabrics’ maximum biosorption capacities for this dye ranged from 12.94 to 18.97 mg/g, while the equilibrium adsorption data were highly consistent with the Langmuir isotherm model. Moreover, based on the predicted dye pKa values, the fabric zeta potential, content of carboxyl and aldehyde groups as well as hydrogen bond intensity (determined by ATR-FTIR), a possible mechanism of the dye biosorption onto jute fabric waste was proposed. Keywords: Jute; Chemical modification; Alkali; Oxidative; Sorption properties; Capillarity

References

Aleksandra Ivanovska, Jelena Lađarević, LeposavaPavun, Biljana Dojčinović, Ilija Cvijetić, DušanMijin, Mirjana Kostić, “Obtaining jute fabrics with enhanced sorption properties and “closing the loop” of their lifecycle, Industrial Crops and Products, Volume 171, 2021, 113913, ISSN 0926-6690, https://doi.org/10.1016/j.indcrop.2021.113913. (https://www.sciencedirect.com/science/article/pii/S0926669021006774)